F1 Aerodynamics & Engineering

Aerodynamic drag is the single most important performance parameter in cycling.

F1 Aerodynamics

State-of-the-art cycling products. Coming from F1 means bringing the absolute leading methods in structural design to the cycling industry.

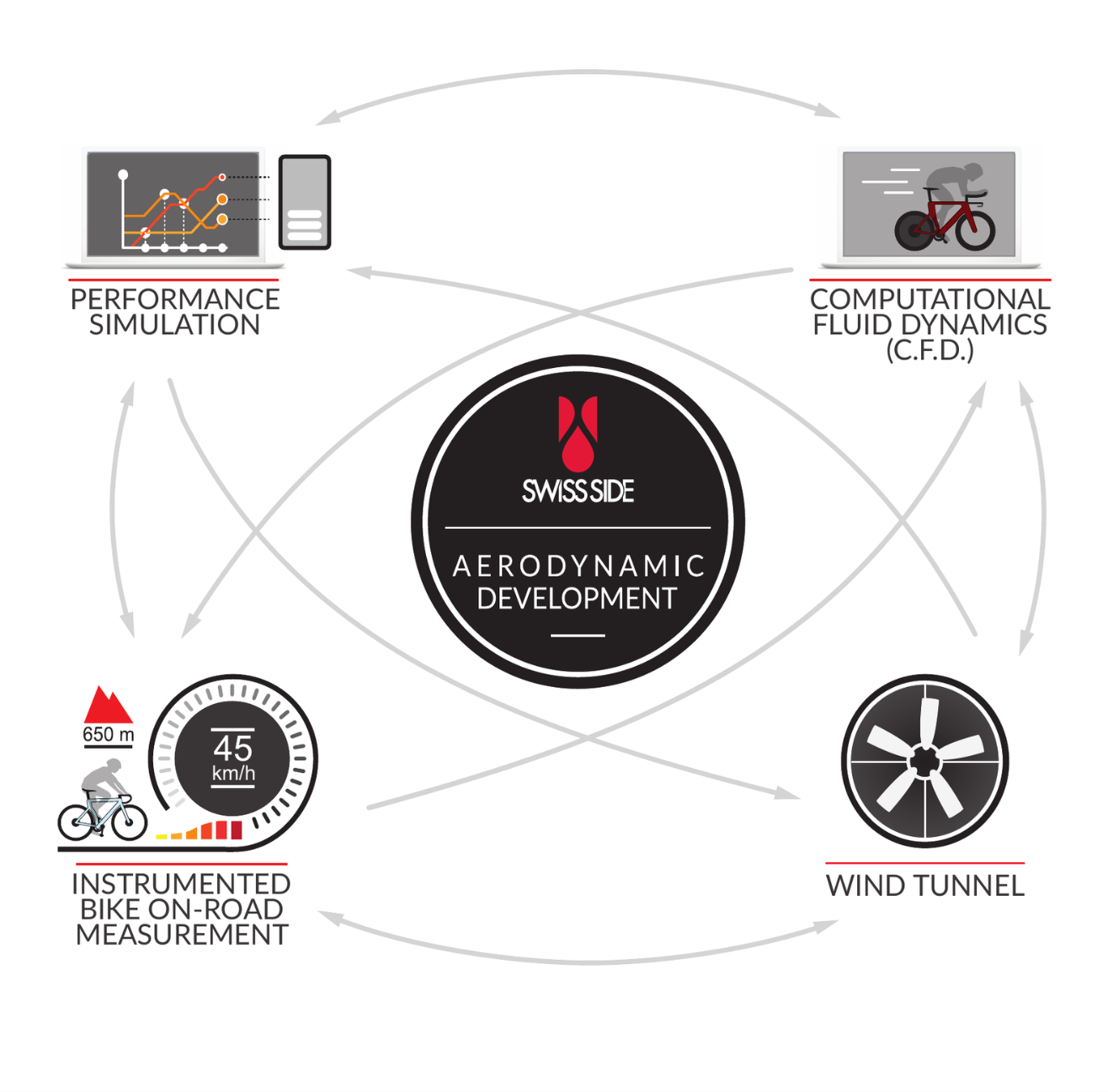

Swiss Side`s unique

4-arm development process

Swiss Side is revolutionising aerodynamics in cycling with an unprecedented, unique 4-arm, interlinked aerodynamic development process. This delivers true "real world performance" out on the road where it matters.

More advanced than any other in the cycling industry.

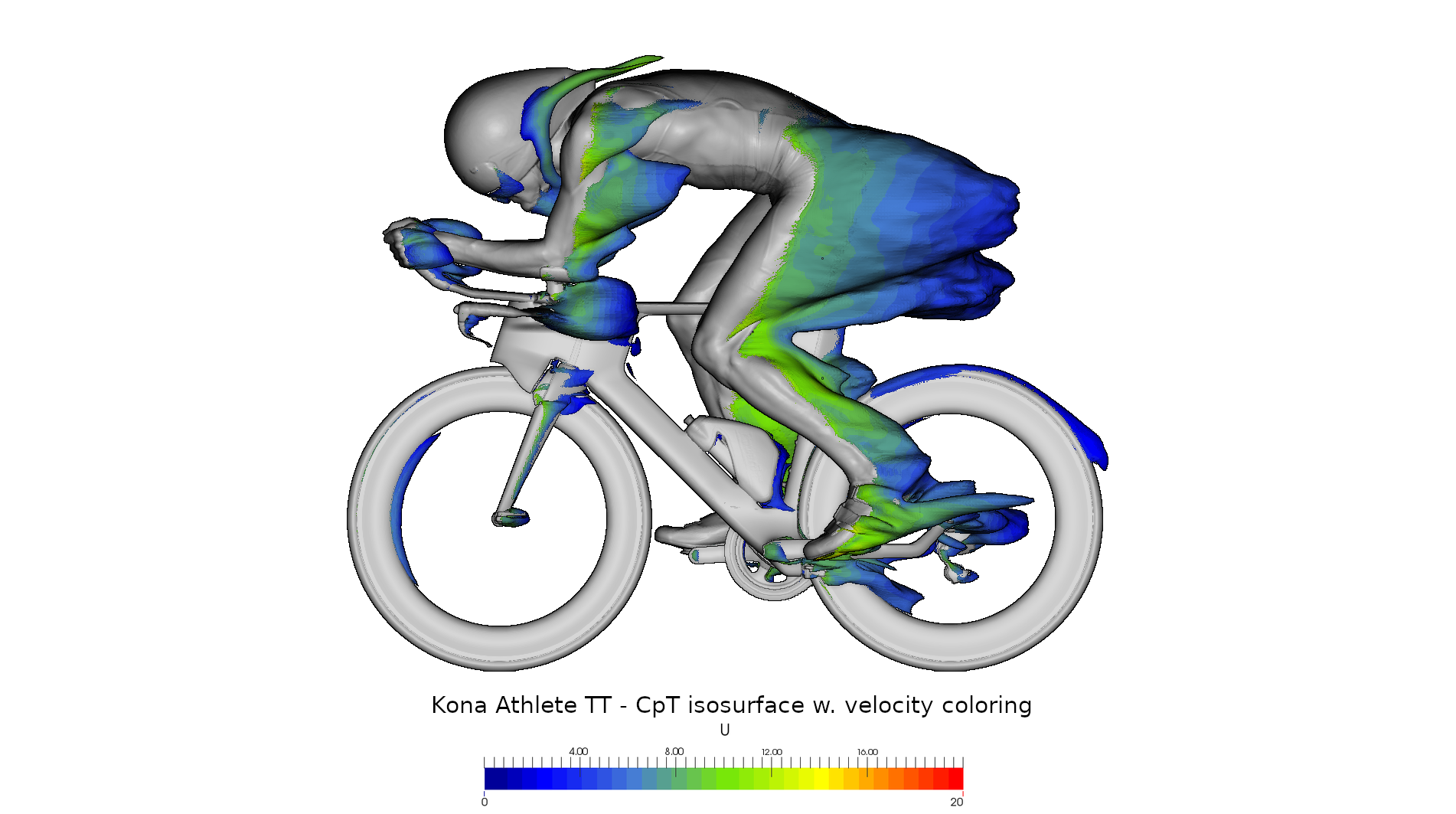

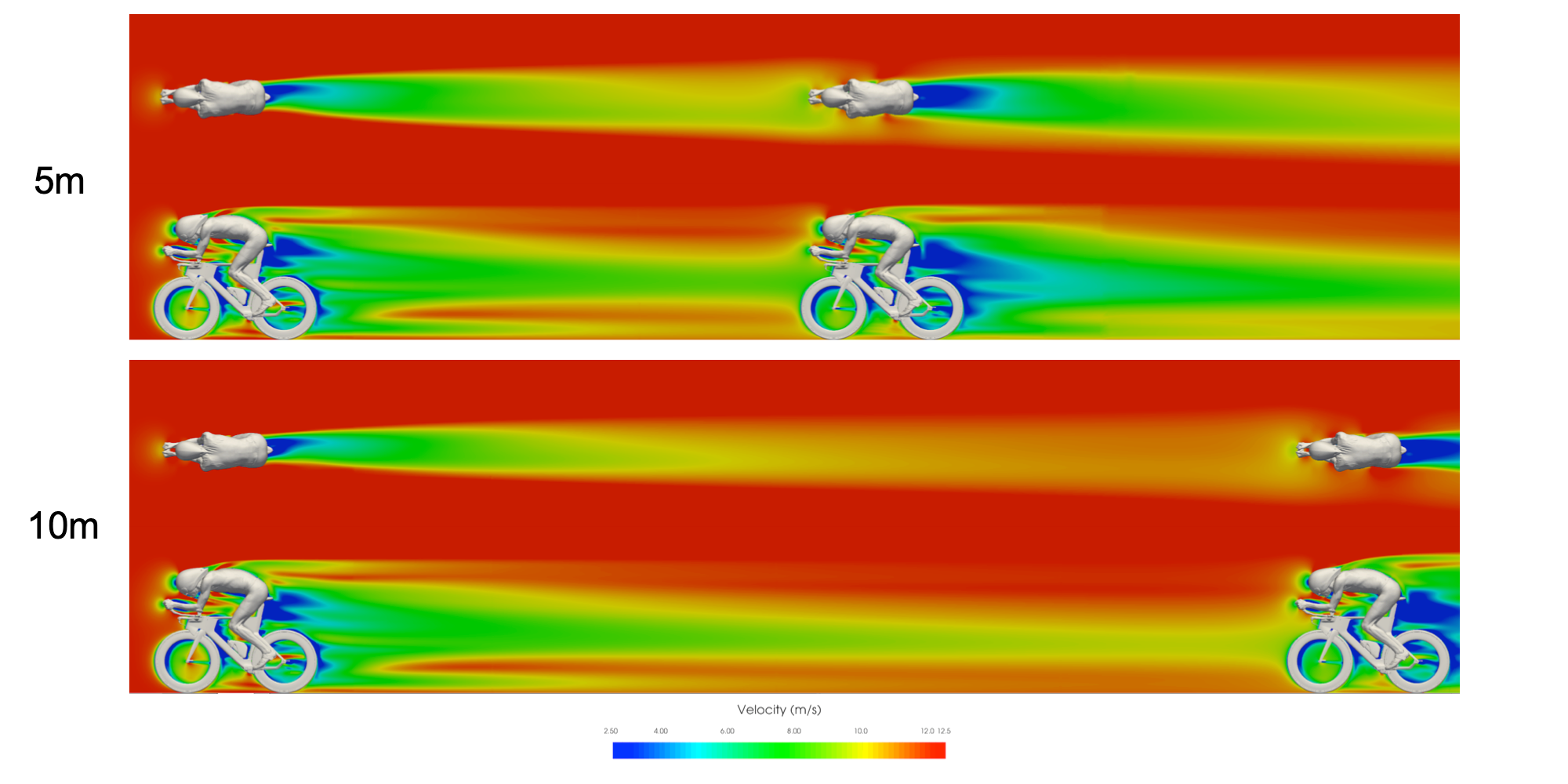

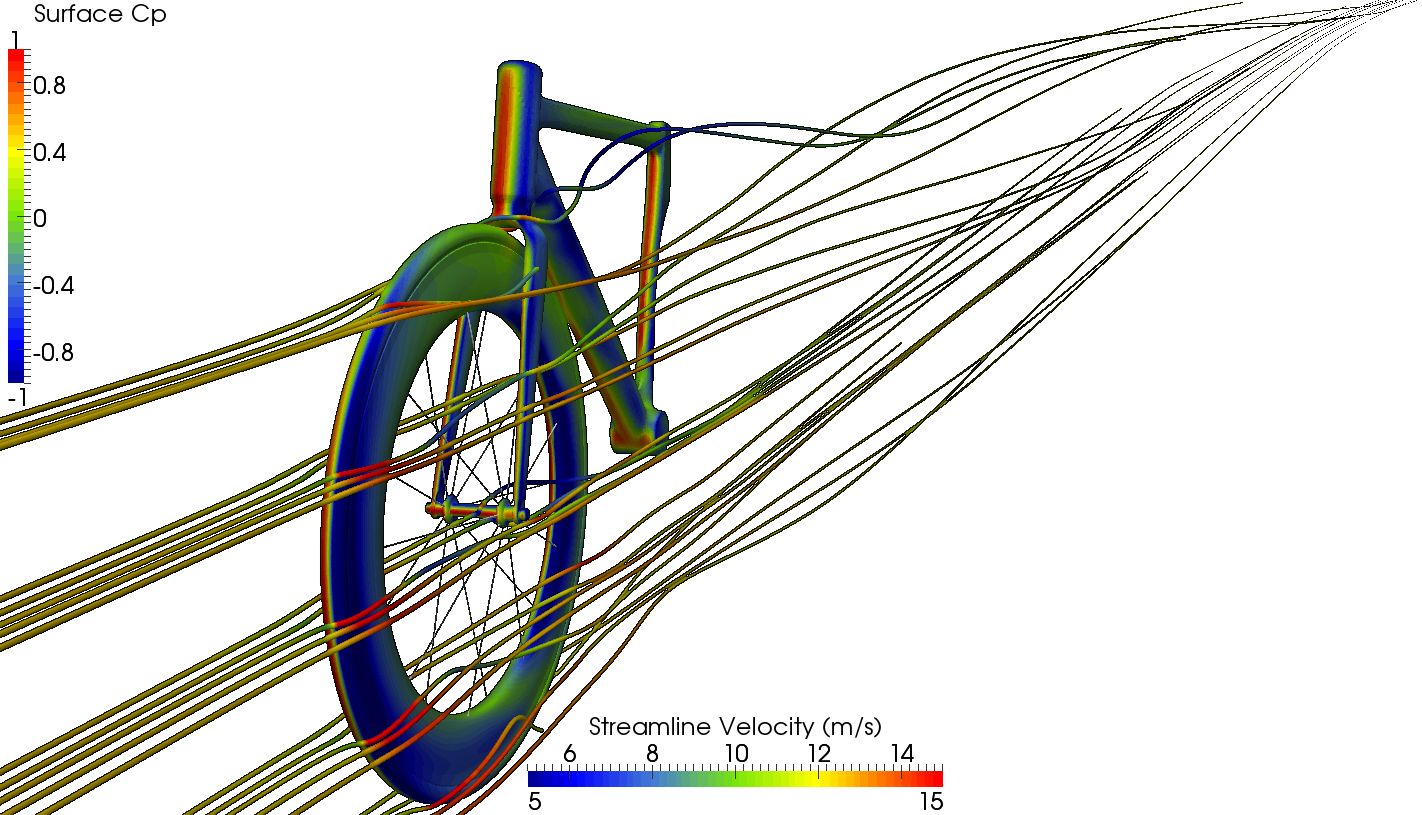

Computational Fluid Dynamics (CFD)

With know-how and the latest methods taken directly from the closed circle of Formula 1, Swiss Side takes CFD simulation to new levels in the cycling industry.

Swiss Side's unmatched CFD methods for unrivaled aerodynamic development

Unleashing the Cutting-Edge

In particular, a combination of steady state and transient (real time) flow simulation methods provide a depth of understanding not possible with other methods.

In house developed data processing tools supply data, which when combined with the additional data Simulation, provide an unequalled level of understanding and aerodynamic development capability.

In addition, backed up with extensive wind tunnel correlation testing, Swiss Side’s CFD methods are second to none in terms of closeness to reality.

As well as being a tool for equipment design and athlete optimization, Swiss Side's CFD tools allow for analysis of on-road conditions.

Wind tunnel testing

We test athletes, materials, and products in our wind tunnel facilities. The Swiss Side aerodynamic team is a mix of highly experienced F1 engineers with backgrounds in aerodynamic development, experts in R&D of aerodynamics, and cycling enthusiasts with a passion for speed and aerodynamics.

Unique measurement systems have been developed such as steering torque for front wheel characterisation, as well as laser positioning systems for complete rider testing.

In house developed data processing tools supply data, which when combined with the additional data Simulation, provide an unequalled level of understanding and aerodynamic development capability.

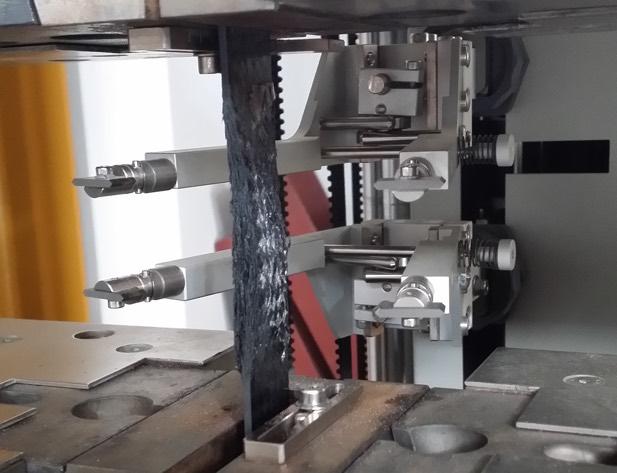

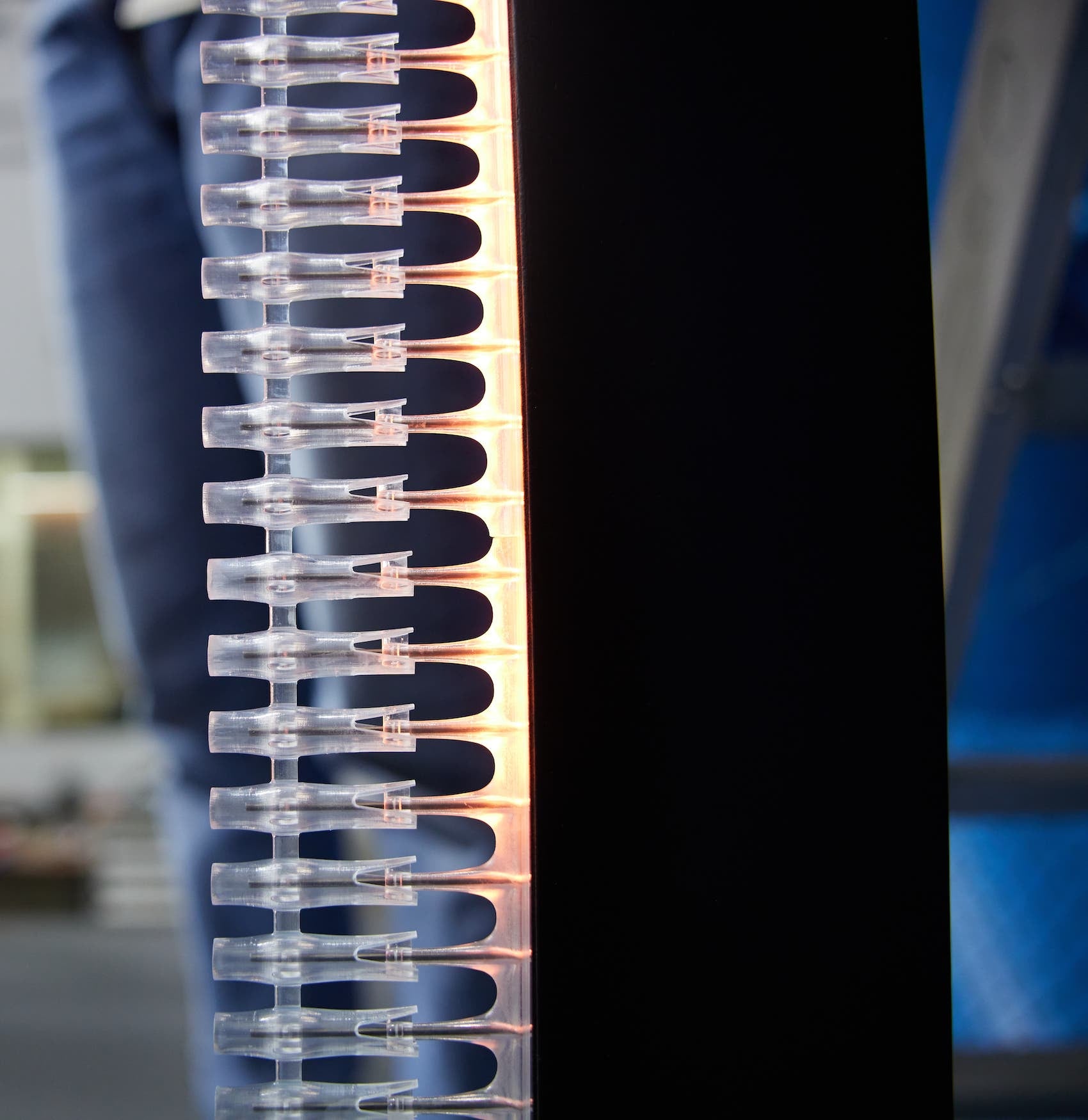

Pressure measurement rake

Breakthrough technology for aero development in the wind tunnel with Swiss Side's pressure measurement rake.

Built from scratch by Swiss Side engineers, this state-of-the-art, never-seen-before technology is designed to not only measure aerodynamic drag, but to visualise it too, measuring energy lost in the airflow behind an object.

It does this using an array of 128 kiel probes for measuring the pressure, which are illuminated by 288 individually controlled LEDs, which change color live and depending on the measured air pressure.

The ‘Swiss Side Aerodynamics’ activities now reach well beyond cycling, with activities in all kinds of aerodynamic development projects across a wide range of industries from sports to automotive. The pressure measurement rake provides a hugely valuable development tool for any application. It also provides extremely useful data for correlation back to the CFD (Computational Fluid Dynamics) simulation models, which further improves and refines the development process.

Quantifying ‘Real World Performance’ to direct development where it matters

Performance simulations

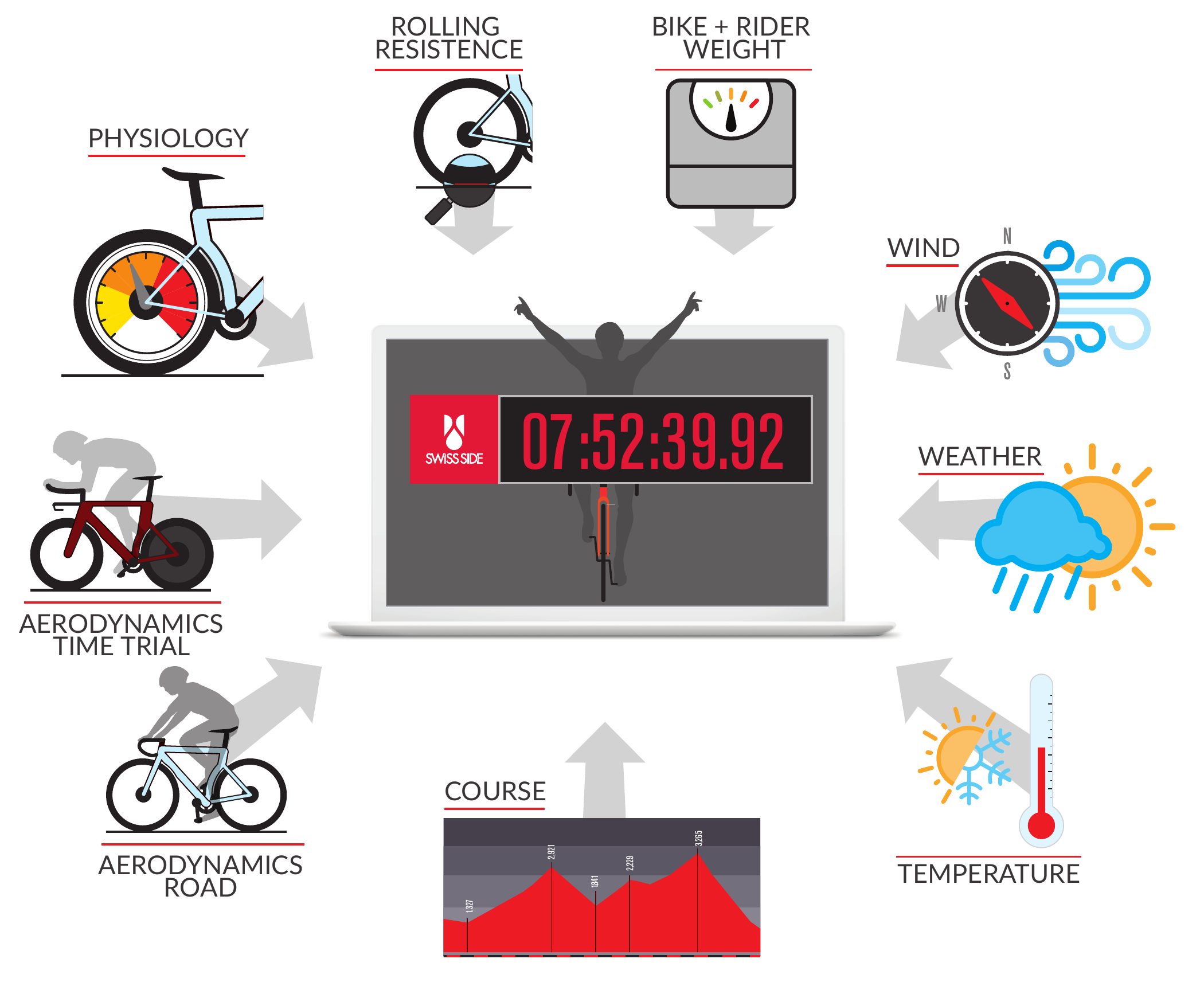

Time on the stopwatch, is the only thing that matters. To quantify aerodynamics and other performance parameters such as weight in an understandable way, Swiss Side uses advanced in-house developed simulation tools for calculating the time deltas of any configuration, on any course.

The data trends from CFD, Wind Tunnel, Instrumented Bike, or any scenario of choice can be input into Swiss Side’s Performance Simulation toolbox. The time gain or loss over a particular course can be estimated, taking into account course profile, bike and rider weights, power output, rolling resistance, wind, aerodynamic drag, etc. In this way, product performance can be better understood and quantified at any point, in the concept phase, during the development process, or once products are on the road.

Swiss Side CDA Meter

Swiss Side develops on-road measurement systems to measure aerodynamic performance out on the road where it matters. This measured data is then used to ensure that CFD and wind tunnel improvements can be measured in the real world.

It importantly also measures the rider’s reaction to external inputs such as wind and like this, better products can be designed to suit the rider’s needs.

The new generation of on-board aero device is the Swiss Side CdA meter - the wind tunnel for the road. It combines the understanding learnt from years of research with the instrumented bike, into a compact system which can be fitted to any bike.

Measurement rake system testing with Patrick Lange

Patrick Lange testing with the Swiss Side Pressure Measurement Rake System on the Salzburgring race track.

n this video, see behind the scenes of the wind tunnel testing and on-road testing with Patrick Lange, using the Swiss Side Pressure Measurement Rake System.

Aero Preparation for Team INEOS Team Time Trial

The Swiss Side Pressure Measurement Rake System in the wind tunnel with Team INEOS.

In this video see the details of how Swiss Side and Team INEOS implement the wind tunnel and pressure rake measurements into optimising rider setup and gathering data for the 'Virtual Pitwall’ performance simulation tool.

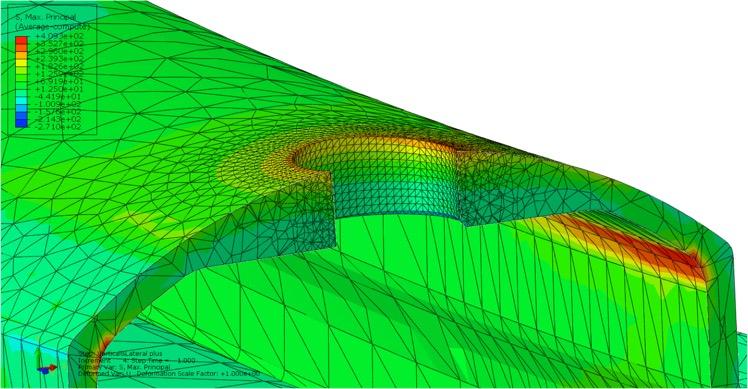

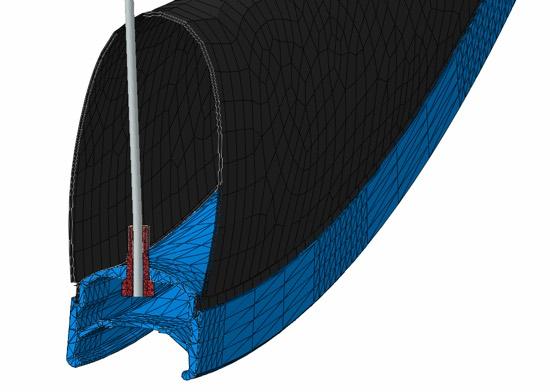

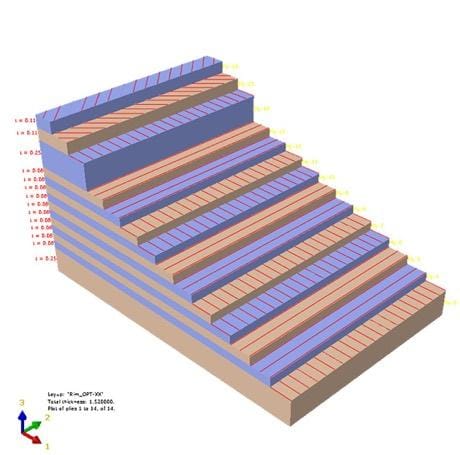

F1 Engineering

Structural engineering. The absolute leading methods in structural design. Swiss Side also uses the absolute leading methods in structural design, once again tapping into the engineering team’s extensive Formula 1 experience.